|

Quanzhou Chuangda Machinery Manufacture Co., Ltd.

|

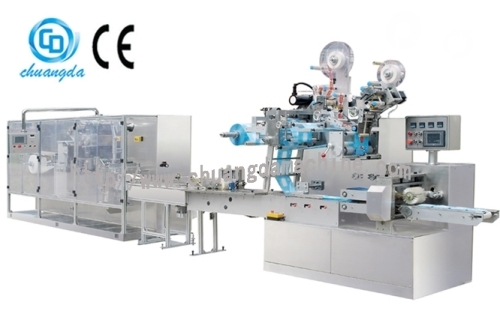

wet tissue making machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Fujian, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Wet tissue making machine price good quality machine

Full automatic & high speed

For 5-30pcs/pack

CE & BV certified

Professional Manufacturer

1. Main technical parameter of making machine

Suitable material:Spunlace non-waven fabric,Hot-rolling non-woven fabrecs

Electrical source: 380V 50HZ

Total power: 21 KW (folding unit:15 KW, packing unit: 6KW )

Special configuration: Stainless steel machine crust

Material:40gsm-80gsm

Production size(unfolded):(160-220mm)*(180-220mm)(L*W)

Production size(folded):(80-110mm)*(70-80mm)(L*W)

Finished products of packing size: (140-180mm)*(70-90mm) *(10-30mm) (L*W*H)

Production speed:200-300pcs/min

Folding type: "Z" fold and double "Z" fold

Counting system: Automatic stacking unit

Packing speed: 35-40 package/5 pieces/min,18-25 package/10 pieces/min

Raw material size: 1200 Diameter*(100-250)* Width

Labelling system: Double labelling system(Included the small labelling uint)

Other function: Placket unit, Labelling unit, Date printing unit.

Control system: Adopt PLC control system, Color touching screen

Packing film size: diameter 400mm

Water tank capacity: with automatic agitation unit with 600 L (2000x1100x1900mm)

Packing film material: OPP/PE PET/PE

Machine size: (8000-9300)x1100x2200 mm (L*W*H)

Machine weight: 4800kg.

2. Machine Introduction

The flowing chart of CD-2008 full automatic wet tissue making machine is:Raw material →splitting→folding→moisture→cutting→pile→coutnting→transport→packing→finishing. All processes (from raw material to finishing production) are finished on the machine.It is sanitary in the producing processes,the speed is fast. This machine is suitable for making 5-30 pieces/package wet tissue.The quantity of every package can be seted and changed easy for your requestment. The operation is easy and the function is very steady. The part touch with liquid is made by stainless steel, the machine is controlled by PLC, there is a conveyor cover protection unit, the machine with beautiful outline.

3. Photos

3. Photos

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Wet Tissue Machine

Wet Tissue Packing Machine

Wet Tissue Packaging Machine

Wet Tissue Folding Machine

Tissue Making Machine

Wet Tissue

More>>